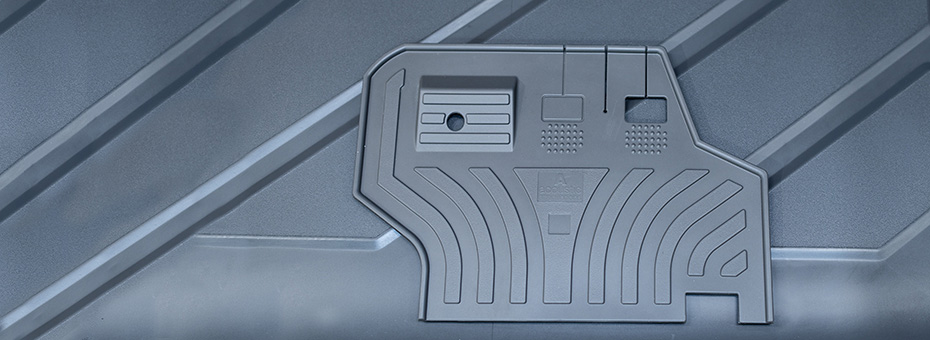

Rotational Moulding

Rotational moulding, or rotomoulding, is a highly versatile method for making precise, stress and seam-free plastic components at comparatively low cost. Click here to see more about the Tecni-Form Rotomoulding process.

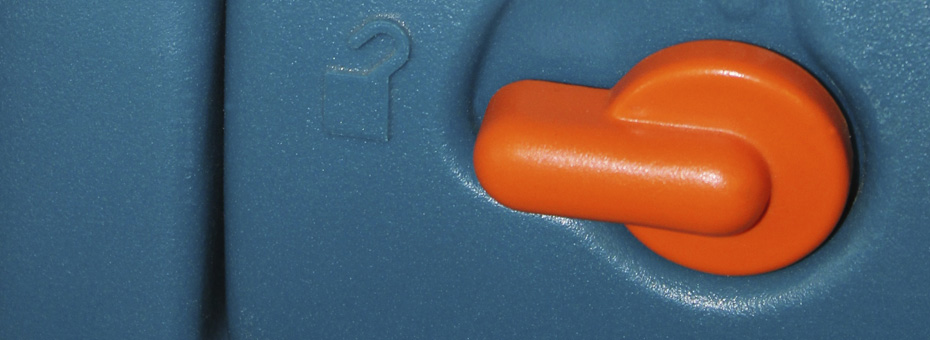

Reaction Injection Moulding (RIM)

Capable of being produced in rigid or flexible form, RIM offers a highly versatile solution for the manufacture of components in low, medium, or high quantities. RIM enables the structure to be solid or foam, with foams available with optional integral skin. Click here

RIM for Prototypes

Low initial costs enable RIM to be an excellent choice for medium to large size prototypes. From one-off to short evaluation runs, RIM offers a cost effective solution. Click here to read more.

Why Choose Tecni-Form?