The reliable procurement of components from Tecni-Form

Luxury Car Parts

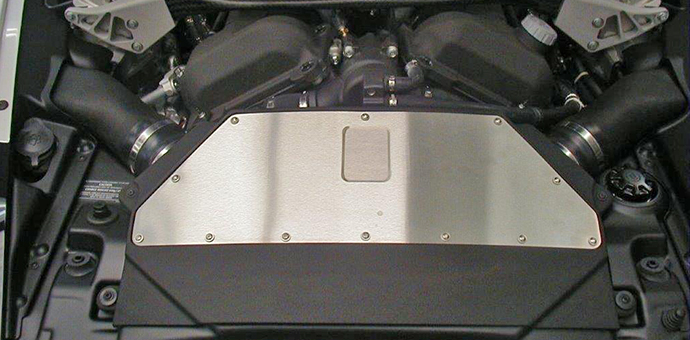

Every industry demands competitive costs, none more than the automotive sector. Rotomoulding & RIM of plastic parts, offers a cost effective solution for the supply of components for small to medium quantity applications. But there is no need to compromise on style and quality in such situations. Indeed, Tecni-Form’s expertise in surface finishing is second to none: they can texture a part in almost any way and can treat a surface so that it can be sprayed to match exactly your major assembly.

Tecni-Form have produced such components as heater ducts, aircon housings, consoles, flexible gaiters (boots), seat parts, spare wheel covers and fluid reservoirs – to name some examples. Some contain embedded metal parts such as threads or unions. Tecni-Form produce an air conditioning ducting assembly containing rotational and injection mouldings, metal pressings and fasteners, ready for installation, for a manufacturer of UK built luxury cars.

Rotomoulding & RIM is particularly cost-effective for prototypes and shorter production runs.

With the right combination of metals, foams and plastics, it is possible to make a reliable engineering component with predictable behaviour under load. Have you considered enlarging the number of components which use this comparatively inexpensive process? Speak to the Tecni-Form design department: they are full of ideas and happy to help.

Optimising Components for Lorries & Buses

Trucks and buses have become stylish as well as being durable workhorses. Attractive styling is often easier to achieve with the rounded and textured lines of plastic mouldings. Rotomouldings produced by Tecni-Form can be made in almost any colour and texture, including exactly matching the colour of the major assembly or vehicle under consideration. If the part does not show, however, recycled plastic can be used that would give a worthwhile cost saving.

Not only is elegant detailing possible but, by using rotational and RIM moulding, it can usually be done at lower cost than with other processes because tooling is much cheaper. This makes rotomoulding and RIM especially suitable for shorter production runs and for prototyping.

Tecni-Form have the edge on most other moulding companies in their well-developed capability to assemble multiple plastic and metal parts completely ready for you to fit. Furthermore they can take complete charge of sourcing the parts for you.

Maybe you are wondering whether to use plastics more in your area of interest. Have a look at the section of this site describing the full rotational moulding process. You may find something that gives you an idea. If you want to discuss a project, you will find the Tecni-Form design department are happy to talk to you.